Your Cart is Empty

Free shipping on online orders over $100 - Some large item exclusions apply

Free shipping on online orders over $100 - Some large item exclusions apply

A Minnesota aggregate company recently turned to Graco for an automatic lubrication (Auto Lube) solution on their rock crusher, one of the most rugged pieces of equipment. Dakota Aggregates produces high-quality, consistent aggregates to serve an ever-evolving construction industry, where their primary goals have become maximizing tonnage and reducing downtime. Watch this video to see how Graco’s auto lube system is helping this aggregate plant reach their goals.

This Graco G3 install was done on a rock crusher with 12 critical bearings to grease, while the machine runs 20 hours per day, on average. Before automatic lubrication, these bearings were greased manually twice each day, posing numerous safety risks as the machine operator has to crawl up and down the machine greasing from head to tail.

IMPROVING MAINTENANCE CYCLE

Proper lubrication is critical when striving to reduce downtime and maximize operating hours to meet demands. Jason Kath, Dakota Aggregates foreman, explains, “It improves downtime, compared to other equipment [on which] we have had to change several bearings — on this machine we have not had to change a bearing yet in the last year and a half.”

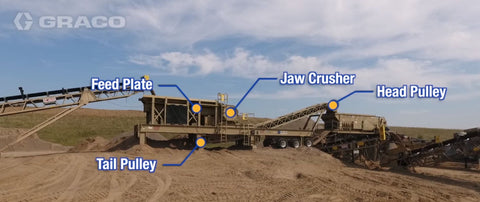

Typically refilling the lubrication system with grease once a month, the rock crusher’s critical bearings are automatically greased every 45 minutes while the machine remains operational. Automatic lubrication systems apply calculated amounts of grease to each lube point, avoiding over- or under-greasing and wasted grease. The locations being greased on the rock crusher are the Head and Tail Pulley of the conveyer, the Jaw Crusher and the feed plate. Planning for upfront preventive maintenance can diminish the amount of lost production due to unforeseen repairs.

DATA MANAGEMENT SYSTEM

The Graco G3 Max system is monitored and equipped with a lube indicator and a beacon that turns red when the system is low on grease. Kent Wanous, machine operator, explains just how the auto lube system makes his job easier: “When there is a fault, the data management system is very beneficial to find out how long and where we were having problems.” Graco G3 Max pumps are equipped with simple data transfer from a flash drive to your PC. This provides performance history for lube system events, such as cycle detection and error logs and allows a quick check of lubrication performance to meet your system requirements.

Built with durability to withstand a tough industry, the auto lube system ensures that the machine continues to produce quality aggregates, reduces downtime by minimizing risks of over- or under-greasing and reduces safety risks. It is the coordinated efforts between the OEM, the dealer and the end user that ensure the best possible solution for each customer’s specific application.

* All trademarks appearing above are the property of their respective owners.

* For original content please visit Graco.com

Fireball Equipment Ltd.

16815 117 Avenue NW, Unit #110,

Edmonton, AB T5M 3V6

Phone: (780) 944-4819

Fax: (780) 944-4898

Email: info@fireball.ca

For Parts And Service

Edmonton: (780) 944-4819

Calgary: (403) 776-0605

Saskatoon: (306) 717-2125

Regina: (306) 216-6534

Vancouver: (236) 259-1883

Winnipeg: (204) 500-0797

Mississauga: (437) 253-4400